Piezoelectric Ceramics

Piezoelectric ceramic products function as components in devices across different fields.

Although not usually visible, this page provides a glimpse into what they are and how they contribute to our lives.

What are piezoelectric ceramics?

Piezoelectric ceramics are a type of electronic ceramics.

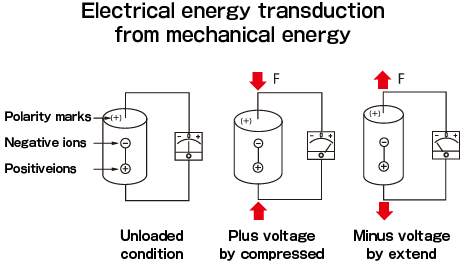

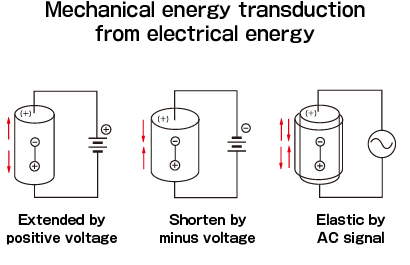

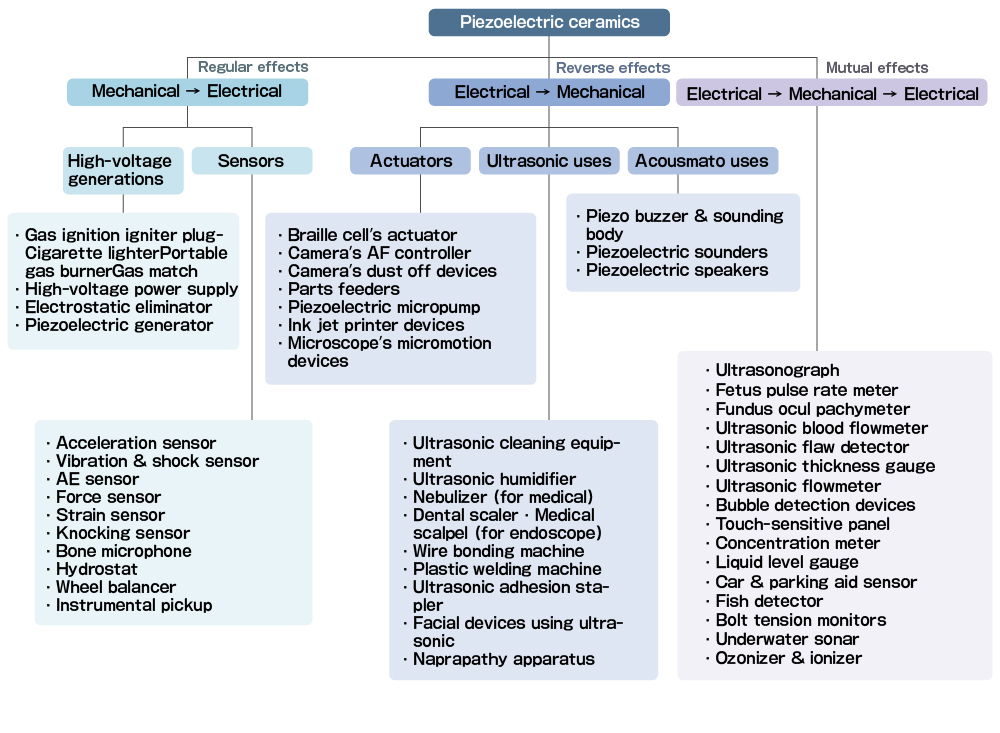

Tapping piezoelectric ceramics generates instantaneous high voltage. Conversely, applying a voltage causes the piezoelectric ceramics to expand and contract.

Piezoelectric ceramics are ceramics that can convert between electric energy and mechanical energy.

Products utilizing these characteristics are used in a wide range of fields, including home appliances, medical, automotive, and industrial fields.

FUJI CERAMICS offers elements suited for diverse applications through its integrated processes from research and development to manufacturing by selecting the most appropriate materials from its abundant piezoelectric ceramic material groups.

- Energy conversion mechanism of piezoelectric ceramics

- Piezoelectric ceramic materials

-

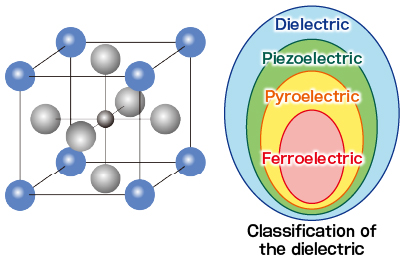

Among piezoelectric ceramics, Lead Zirconate Titanate (Pb(Zr・Ti)O3), commonly known as PZT, demonstrates significant piezoelectricity and is a ferroelectric material with a crystal structure referred to as perovskite.

With an elemental composition consisting of lead titanate [PbTiO3] and lead zirconate [PbZrO3], PZT’s physical properties, such as piezoelectricity, dielectricity, and elasticity, can be controlled by changing the mixing ratio of these two components, making it possible to create tailor-made piezoelectric ceramics suited for your applications.

Piezoelectric materials are characterized mainly by the reversible conversion between electric energy and mechanical energy. In addition to soft and hard PZT materials that have such characteristics, FUJI CERAMICS offers other piezoelectric ceramic elements, such as lead titanate [PbTiO3], lead metaniobate [PbNb2O6], and bismuth titanate [Bi4Ti3O12].

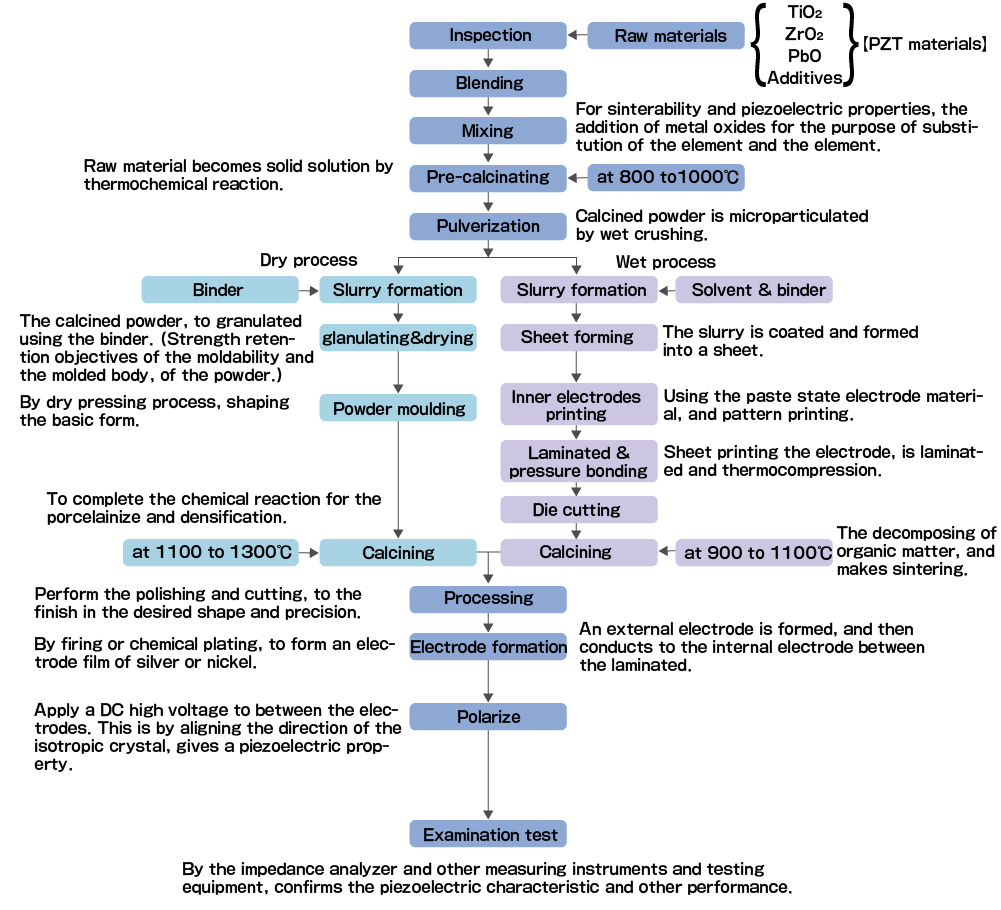

Manufacturing processes

Piezoelectric ceramics are polycrystalline substances. The work process for piezoelectric ceramics is broadly divided into the ceramic powder manufacturing process and the firing process, in which the ceramic powder is molded into products and heated to high temperatures to bond particles.

This work process is followed by blending additives to obtain the electrical properties required for the purpose and application and by the polarization treatment by which a high DC voltage is applied to the element at high temperatures to align its crystal orientation.

Piezoelectric ceramic products

The application fields of piezoelectric ceramics can be roughly divided into vibrators and transducers.

An vibrator is used for electrical input to mechanical vibration to electrical output and includes ceramic oscillators, filters, piezoelectric buzzers, and piezoelectric transformers.

Transducers are devices that utilize electrical input to produce mechanical output and include ultrasonic cleaners and actuators. Transducers are also used for mechanical input–electrical output applications, which include vibration/shock sensors and piezoelectric generator elements.

The practical applications of piezoelectric ceramics cover a wide range of fields. The following introduces some of the application fields.

Overseas Sales Section.

+81-544-58-4466

Service hours: Monday to Friday 8:00 to 17:00

(Closed Saturdays, Sundays, and holidays)